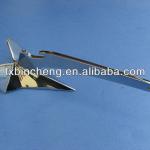

precision casting for detachable anchor connecting link boat parts casting china

detachable anchor steel casting, 1.10 years casting experience, 2.Carbon steel&alloy steel, 3.Lost wax, 4.ISO9001,TS16949 - details see: https://www.vehicleto.com/precision-casting-for-detachable-anchor-connecting-link-boat-parts-casting-china-10032339

| Material: Steel,Carbon steel & Alloy steel | Certification: LR | Weight (kg): < 1000kg | Process: Lost wax technology/Dewax |

| Dimension tolerance: CT7 | Casting weight: 0.10-100kg | Max casting size: 1000mm | Standard: GB,ASTM,AISI,DIN,BS,JIS |

| Post-processing: Heat treatment | Machining: CNC machining | Testing: Magnetic Particle Inspector, CMM, Ultrasonic flaw Inspector, Etc. | Surface treatment: Zinc plate, chrome plate, polishing, paint, powder coat, Etc. |

precision casting for detachable anchor connecting link boat parts casting china

| Material Standards |

| ANSI/ASTM, BS, DIN, JIS and ISO, including carbon steel and alloy steel. |

| MAIN PRODUCTS |

| Precision Casting, Precision Machining. |

| MACHINING CAPABILITY |

| All types of cnc machining centers,cnc turning,milling, lathes, drilling, handing lathes. |

| SURFACE TREATMENT CAPABILITY |

| Zinc plate, chrome plate, polishing, paint, powder coat, shot blast, sand blast, grinding. |

| CERTIFICATES |

| ISO9001, TS16949, ABS, BV, DNV, GL, LR, KR. |

| Production Equipment List | ||||

| No. | Equipment | Quantity | Age | Model |

| 1 | Intermediate Frequency Induction Electric Furnace | 4 | 1-6 | KGPS1000-300 |

| 2 | Wax-spraying Machine | 6 | 4 | |

| 3 | Crawler Abrators | 5 | 2-5 | Q3210 |

| 4 | Conveyor type Abrators | 2 | 2-3 | Q378 |

| 5 | CNC Turning | 4 | 5 | CNC6150A |

| 6 | Lathes | 17 | 2-6 | CY6140*1000 |

| 7 | Drilling | 8 | 6 | 23050*16 |

| 8 | Milling | 9 | 7 | XQ6230B |

| 9 | Planer | 1 | 8 | |

| 10 | CNC Machining Centers | 2 | 2 | VMC1100B |

| Testing Equipment List | ||

| No. | Equipment | Quantity |

| 1 | Low-temperature Impact Device | 1 |

| 2 | Magnetic Particle Inspector | 1 |

| 3 | Tensile Tester | 1 |

| 4 | Metallography Automatic Analysis | 1 |

| 5 | Spectrometer | 1 |

| 6 | CMM | 1 |

| 7 | Ultrasonic Flaw Inspector | 1 |

| 8 | Hardness Tester | 1 |

| 9 | Pull Slot Machine | 1 |

| 10 | Impact Testing Machine | 1 |

| 11 | Projector | 1 |

| Working Process | |

| No. | Process |

| 1 | Injecting wax |

| 2 | Remove the burrs |

| 3 | Welding |

| 4 | Making the shell |

| 5 | Dewax |

| 6 | Shell baking |

| 7 | Pouring |

| 8 | Testing |

| 9 | Remove the shell |

| 10 | Cutting the pouring gate |

| 11 | Grinding the pouring gate |

| 12 | Sand blasting |

| 13 | Heat treatment |

| 14 | Machining |

| 15 | Inspection |

OUR MAIN PRODUCT CATEGORIES

•Engineering Machinery Parts

• Automobile Parts

• Marine Parts

• Machining Parts

• Hydraulic Valve Parts

• Oil and gas fields Parts

• Farm Machinery Parts

• Transmission Line Accessories

| Packaging Detail:Wood package for export |

| Delivery Detail:4-6 weeks |