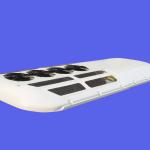

HSQ2400 Electromagnetic Retarder

| Type: retarder | Size: 534mmX580mmX295mm | Material: cast iron,aluminum | Bus Model: Yutong,Kinglong,Ankai,Golden Dragon, Daewoo, Tata |

| Number of R&D Staff: 41 - 50 People | Management Certification: ISO9001 ISO/TS16949 ISO14001 |

HSQ2400 Electromagnetic Retarder

HSQ Series of Electromagnetic Retarder

Application:

HSQ series of automobile electromagnetic retarders are the environment-protective hi-tech products, designed upon the principle of electromagnetic mechanics, which are used

as a necessary supplement for the brake system, offering auxiliary braking force to the brake

system. As a result of this, the easement and security of vehicle running have been promoted

greatly and for the brake disks, tires and braking system, wear and tear have been reduced so

as to prolong their service lives. Furthermore, the maintenance fee can be saved a lot. In the

meantime the noise and powder causing pollution have been reduced a great deal owing to the

use of the retarder. The ratarder is specially applied to medium and heavy cargo trucks,and top-graded passenger cars.

Briefs of the structure

HSQ series of speed reducer mainly contains following parts:

1) interface bracket

2) rotor

3) stator

4) coil

5) mid joint flange

The interface bracket (part1) is to be cast precisely and mounted on the chassis or car body. The rotor (part2) which are divided into two parts (front and back) are to be cast with light and fine ferrous magnetic materials containing good magnetic conductivity and it is specially made into a form of blade wheel in order to dispel the heat caused by braking. The two rotors are mounted on two sides of the stator in symmetry through the mid joint flange (part 5), keeping with an appropriate gap (adjusted by spacer). The stator (part 3) is a stamping workpiece made of light and high strength material that is magnetic-proof. Around the outside circle of the stator are mounted four sets of magnetic coils with unlike poles, which are wounded on 8 magnetic cores with high magnetic conductivity. The coils (part 4) are to be winded with wires containing characters of high heat resistance and high electric conductivity and be divided into four groups (each group has two) with unlike poles. The mid joint flange (part 5), which is made of fine material by precise machine, is to be connected with the driving shaft of the automobile.

| Packaging Detail:AS YOUR REQUIREMENTS |

| Delivery Detail:20 DAYS |