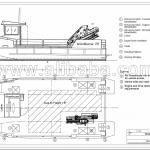

400ft Liftboat

| Length overall: 74.784m | Breadth molded: 44.806m | Depth molded: 6.20m | Design draught: 3.40m |

| Design speed: 6.0kn | Max. Jacking load: 7200t | Variable load: 1750t | Service depth: 5-75m |

| Air gap: 20m | Main deck area: ~1700m2 |

This unit to be designed as a workover and well service under the condition of 76.2m(250ft)sea water depth. The deck area of the unit to be about 1700 m2which carry a 250t crane for offshore service, and the unit also can be also applied as a living support vessel

2 General Description

Hull Particulars:

Length overall 74.784 m

Breath molded 44.806m

Depth molded 6.20 m

Design draught 3.40 m

Design speed 6.0 kn

Max.Jacking load 7200 t

Variable load 1750 t

Service depth 5-75m (16.4-246ft)

Air gap 20m( 65.6ft)

Deck stress 5 t/m2

Main deck area ~1700 m2

Leg, Spud can and jacking system particulars:

Leg configuration: trigonal truss with spline

Leg lateral: 8.23 m(27ft)

Leg length (including spud can): 120m (393.7ft)

Spud can dimension: Φ15.24m((50ft)X4.572m(15ft)

Jacking system: electric

Jacking speed (under load): 0.457 m/min(1.5ft/min)

Accommodation: 160P

Helicopter: Sikorsky S-61N

3.1The following table presents the upper range of environmental conditions to be used for the structural strength evaluations:

| Environmental criteria | Value |

| Water Depth LAT [m] | 75.0 |

| Wave Height [m] | 12.0 |

| Associated Wave Period [s] | 13.5 |

| Spring tide amplitude [m] | 0.75 |

| 50-yr storm surge elevation [m] | 1.75 |

| Wind [1-minute averaged] [m/s] | 32 |

| Airgap [m] | 20.0 |

| Penetration [m] | 4.57 |

| Minimum Design Temperature | -10° C |

3.2Tank Capacities

The specific tank sizes are to be defined by the tank plan drawing.

| Tank | Capacity(m3) | Tank | Capacity(m3) |

| Ballast tank | 5000 | Lube oil tank | 4.4 |

| Fuel oil tank | 318.8 | Waste oil tank | 10.9 |

| Fuel oil day tank | 320.0 | Bilge water tanks | 33.4 |

4 LEG, SPUDCAN AND JACKING SYSTEM

The leg to be trigonal truss type, with outside of lateral 8.23 m(27ft). The leg length, including spud can, to be 120m (393.7ft). The spud can to be circular, withΦ15.24m((50ft). Each leg to be connected with the hull by means of jacking gear units. The unit to contain the electric motor and jacking pinion. The jacking units are able to jack / lower the leg or main hull according to the operation requirements.

The jacking system to consist of electric control and electric-driven function, and each leg is equipped with six (6) sets of jacking electric motor, planetary gear box, jack pinion, brake, inclinometer etc.

Main parameters:

Normal jacking capacity: 1800 t per leg

Preload holding capacity: 2390 t per leg

Max. Jacking speed (under load): 0.457 m/min(1.5ft/min)

Power source: 600V, 50Hz, 3 phases

Electric Motor Rated Power: 30HP per motor

| Packaging Detail:N/A |

| Delivery Detail:N/A |